1. Executive Summary: Economics and Engineering of DIY Pavement Repair

Degradation of residential driveways—whether asphaltic concrete or Portland cement concrete—is an inevitability driven by environmental thermodynamics, hydrological forces, and mechanical loading. The emergence of potholes, alligator cracking, and spalling represents progressive structural failure that, if neglected, necessitates substantial capital expenditure for full resurfacing.

The contemporary marketplace for pavement preservation has evolved considerably, offering do-it-yourself solutions that bridge temporary stop-gaps and professional-grade rehabilitation. This guide evaluates low-cost, ready-to-use (RTU) solutions for repairing potholes and cracks, prioritizing efficacy, cost-efficiency, and ease of application—particularly for scenarios where heavy machinery is unavailable and professional intervention is economically unfeasible.

Central to this evaluation is the distinction between cold technologies—relying on chemical curing or solvent evaporation—and traditional hot methods, and how recent advancements have made permanent repairs accessible to amateur technicians.

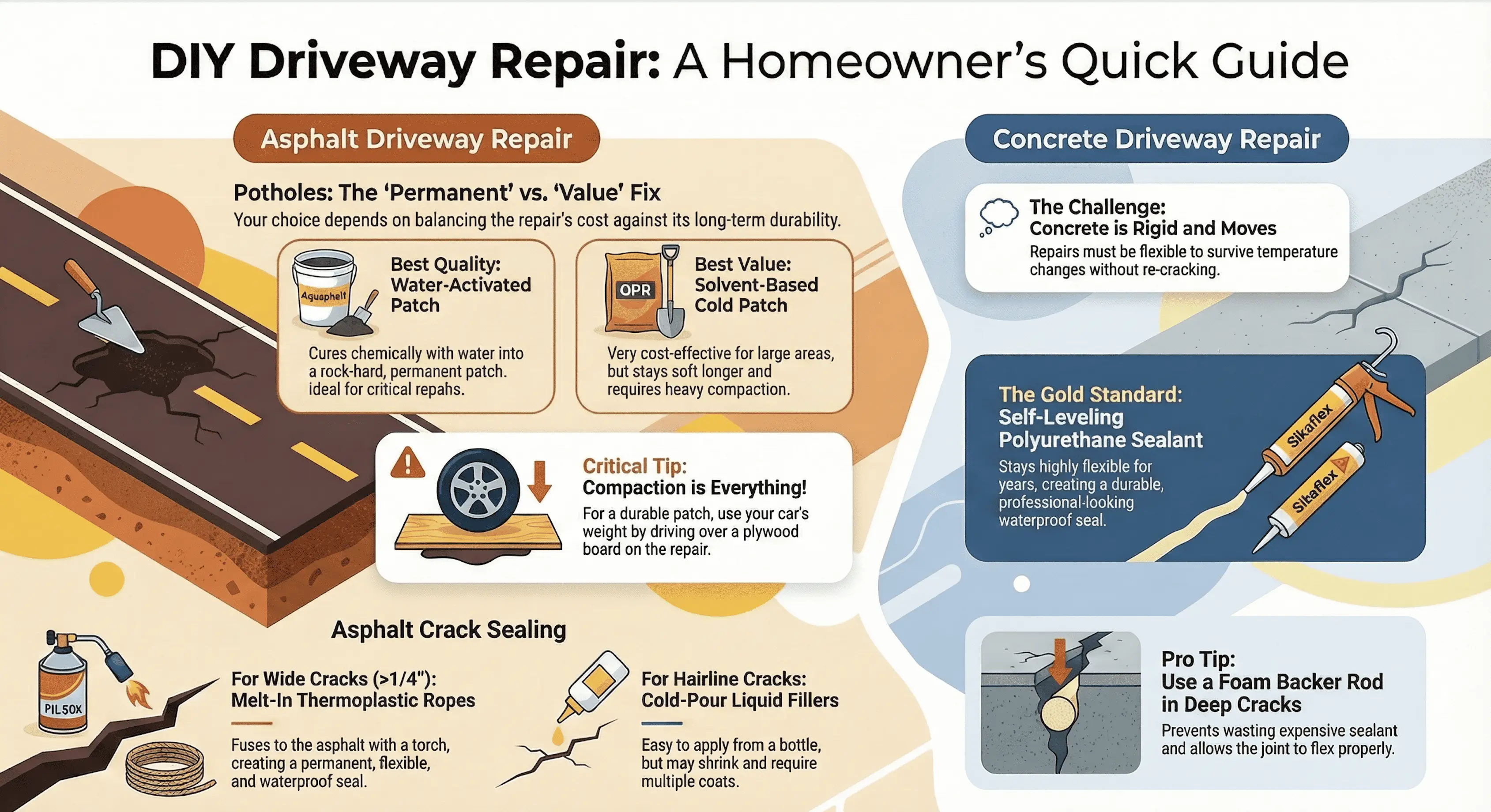

Current market data reveals a bifurcation in DIY solutions:

- Premium water-activated reactive asphalts (e.g., Aquaphalt) offering near-permanent durability at higher price points

- Modified cold-patch composites (e.g., QPR, Road Rescue) providing cost-effective bulk volume for larger failures

Similarly, crack sealing has progressed beyond simple tars to advanced polyurethanes and thermoplastic polymers that accommodate thermal expansion—a critical factor in regions subject to freeze-thaw cycles.

2. Pavement Pathology: Mechanisms of Failure

Understanding underlying causes of pavement distress is prerequisite for selecting appropriate repair solutions. A repair material must address the specific failure mechanism to prevent recurrence; otherwise, the intervention remains merely cosmetic and transient.

2.1 The Hydro-Thermal Cycle and Pothole Formation

Potholes are rarely isolated surface defects—they are symptomatic of deeper systemic failure within the pavement structure, often extending into the sub-base. The process typically initiates with micro-cracking, which compromises pavement impermeability and permits water infiltration.

Infiltration Dynamics: Water permeates the asphalt binder or concrete matrix, settling into the sub-base (gravel or soil) or accumulating within pavement layers. Poor drainage profiles or lack of sealant exacerbate this infiltration.

Saturation and Structural Weakening: As the sub-base becomes saturated, it loses cohesive strength and load-bearing capacity. The soil transforms into a mud slurry incapable of supporting the rigid or semi-rigid pavement layer above.

Freeze-Thaw Expansion: In colder climates, trapped water undergoes phase change to ice, expanding approximately 9% in volume. This expansion exerts significant upward hydraulic pressure (frost heave), displacing the pavement surface and disrupting the interlocking aggregate structure.

Mechanical Fatigue and Collapse: When ice melts, a void remains beneath the surface layer. Subsequent vehicle traffic fatigues the unsupported asphalt or concrete span, causing collapse into the void. This collapse creates the pothole, which then grows exponentially as traffic impacts the defect’s sharp edges.

Key Insight: Effective pothole repair must not only fill the volumetric void but also re-establish the seal against further water intrusion and possess sufficient compressive strength to bridge any remaining sub-base weaknesses.

2.2 Crack Typologies and Thermal Stress

Cracks are primarily categorized by cause and orientation, dictating required elasticity of repair material:

| Crack Type | Characteristics | Cause | Repair Implications |

|---|---|---|---|

| Thermal/Transverse | Perpendicular to centerline; opens and closes seasonally | Volumetric shrinkage during temperature drops | Requires flexible fillers; rigid materials detach during contraction |

| Fatigue/Alligator | Interconnected pattern resembling alligator skin | Structural failure under repeated loads; soft subgrade | Simple pourable filler insufficient; patch or overlay required |

| Settlement | Often near garage aprons or edges | Ground shifting or consolidation beneath driveway | May require base repair before surface treatment |

Rigid materials (mortar or standard concrete patch) frequently fail because they cannot accommodate thermal expansion and contraction cycles. Successful DIY repair requires materials with high modulus of elasticity, such as polyurethanes or thermoplastics.

3. Asphalt Pothole Repair: Cold Patch Technologies

For asphalt driveways, the industry standard for DIY repair is Cold Patch or Cold Mix asphalt. Unlike hot-mix asphalt requiring industrial plants to heat aggregate and binder to 300°F (150°C), cold patch relies on proprietary chemical binders to remain pliable at ambient temperatures until compacted.

3.1 Advanced Reactive Binders (Premium Tier)

Water-activated asphalt, notably represented by Aquaphalt and similar reactive products, represents a technological advancement over traditional cold mixes.

Curing Mechanism: Unlike standard cold patches curing via solvent evaporation (a process spanning months), reactive binders cure through chemical reaction with water. The binder contains prepolymers that crosslink upon moisture exposure, creating a rigid, high-strength matrix comparable to hot-mix asphalt.

Performance Characteristics:

- Hardens significantly within 24 hours

- Impervious to tire tracking immediately after compaction

- Rated for permanent repairs with structural integrity comparable to original pavement

Application Advantage: Water-activation permits effective use even in rain-filled potholes—water accelerates the curing process rather than hindering adhesion.

Cost Implications: Approximately $50–$70 per 50lb bucket—ideal for small, critical repairs where longevity is paramount, but potentially cost-prohibitive for extensive degradation.

3.2 Modified Cutback Asphalts (Volume Tier)

The majority of consumer market consists of “High Performance” cold patches like QPR (Quality Pavement Repair) and Road Rescue—the traditional “bagged asphalt” solutions found in most hardware stores.

Binder Chemistry: These products utilize cutback bitumen—asphalt cement dissolved in solvent (often proprietary oils, biodiesel, or kerosene). The solvent lowers bitumen viscosity, keeping the mix soft and workable. Upon compaction, aggregate locks together, and solvent slowly evaporates over weeks to months.

Performance Trade-offs:

- Remains pliable for extended periods, allowing “self-healing” and movement

- Frequently leads to tracking (sticking to tires/shoes) or deformation without extreme compaction force

- Some users report material remaining soft indefinitely if cutback agents are trapped deep within thick patches

Durability: While marketed as permanent, susceptible to failure if water infiltrates before slow cure completes. However, brands like QPR are DOT-approved and used by municipalities, indicating high reliability when installed correctly with proper compaction.

Cost Efficiency: Approximately $15–$24 per 50lb bag—logical choice for large, deep potholes where material volume is substantial.

3.3 Comparative Analysis of Leading Asphalt Patch Products

| Feature | Aquaphalt 6.0 | QPR Permanent Repair | Road Rescue Asphalt | Sakrete / Generic Cold Patch |

|---|---|---|---|---|

| Binder Technology | Water-Activated Reactive Binder | Modified Cutback (Solvent-based) | Natural Asphaltic Rock / Bio-oils | Standard Cutback Asphalt |

| Cure Mechanism | Chemical Reaction (Fast) | Evaporation / Oxidation (Slow) | Compaction & Evaporation | Evaporation |

| Time to Traffic | Immediate | Immediate (remains soft) | Immediate | Immediate (tracking risk) |

| Full Cure Time | 24 Hours | Weeks to Months | Immediate Hardening | Months |

| Compaction Requirement | Standard Tamping | Heavy Compaction Required | Car Tire / Tamp | Heavy Compaction Required |

| Water Resistance | Hydrophobic upon cure; water aids cure | Permeable until cured; susceptible to washout | Water-resistant | Low until cured |

| Best Use Case | Permanent, heavy-load areas; small holes | Large potholes; budget-conscious repairs | All-weather emergency repair | Temporary fixes; low traffic |

| Approx. Cost | ~$50 / 50lb Bucket | ~$20 / 50lb Bag | ~$23 / 50lb Bag | ~$15–18 / 50lb Bag |

Strategic Insight: Clear trade-off exists between cure speed/hardness and cost. Aquaphalt offers “pro-grade” finish mimicking hot asphalt at 2.5x QPR’s price. For a single 12-inch pothole, Aquaphalt is superior to avoid re-work. For a long rural driveway with dozens of potholes, QPR or Road Rescue provides viable economic compromise, provided rigorous compaction compensates for softer binder.

3.4 The Physics of Compaction: The DIY Challenge

Inadequate compaction is the most common reason for DIY patch failure. Professional crews use vibratory plate compactors or multi-ton steamrollers to achieve density. The DIYer typically has only a hand tamper or shovel.

The Density Imperative: Asphalt strength derives from interlocking aggregate. Without sufficient density, the patch remains porous, permitting water entry and bond destruction.

The “Marshmallow” Effect: If a deep hole is filled in a single layer, the surface may feel hard while the bottom remains loose. Traffic eventually consolidates the bottom layer, causing the surface to sink and form a depression (“dish”) that holds water.

The Vehicle Compaction Technique: A highly effective method for achieving near-professional compaction without renting equipment: place plywood over the slightly overfilled patch and slowly drive a vehicle back and forth. The vehicle’s weight applies thousands of pounds of compressive force—far exceeding hand tamping capability. This technique is particularly crucial for solvent-based patches like QPR.

4. Asphalt Crack Sealing: Liquid Emulsions vs. Thermoplastic Ropes

Crack sealing is the most critical preventative maintenance task. Preventing water from entering the sub-base stops potholes from forming. DIY solutions fall into two primary categories: Cold-Pour Liquids and Hot-Applied Thermoplastics.

4.1 Hot-Applied Thermoplastics (Pli-Stix / Crack-Stix)

Products like Latex-ite Pli-Stix represent miniaturization of commercial highway technology for the DIY market—essentially ropes of rubberized asphalt melted into cracks.

Application Methodology: Solid “ropes” of rubberized asphalt are inserted into cracks and melted using a handheld propane torch or heat gun.

Advantages:

- Self-Leveling & Bonding: Heat fuses material to crack walls, creating watertight bond that liquids rarely achieve. Heat also drives out residual moisture.

- Elasticity: Thermoplastics contain polymers permitting expansion and contraction with pavement without splitting—the only true “permanent” DIY crack filler for working cracks.

- Ready for Traffic: Material cures as soon as it cools, typically within 20 minutes.

Disadvantages: Requires torch (introducing fire hazard and additional tool cost), more labor-intensive than pouring liquid, difficult to apply in windy conditions where torch flame is unstable.

4.2 Cold-Pour Liquids (Asphalt Emulsions)

Products like Latex-ite Driveway Filler or Red Devil acrylics are water-based emulsions poured directly from a bottle.

Application: Simple “squeeze and smooth” operation—the most “ready-to-use” option available.

Advantages: Extremely low cost ($5–$15 per gallon) and approachable for novices.

Disadvantages:

- Shrinkage: Often 30–40% water content. As water evaporates, solids shrink, frequently requiring second coat to fill crack flush to surface.

- Washout Risk: Rain within 24–48 hours of application can re-emulsify uncured emulsion, washing it away and staining the driveway.

- Longevity: Hardening through evaporation often leads to brittleness over time, with re-cracking within 1–2 seasons.

Comparative Insight: For cracks wider than 1/4 inch, rope fillers (Pli-Stix) are vastly superior due to their ability to bridge gaps and move with pavement. Liquid fillers are best reserved for hairline cracks (network cracking) where inserting rope is impossible.

5. Concrete Repair: Managing Rigidity and Movement

Concrete repair requires fundamentally different approach than asphalt. Concrete is rigid, and repairs often fail because patch material (often cite cementitious) shrinks or lacks tensile strength to bond to old concrete.

5.1 Sealant Chemistry Comparison

The modern standard for horizontal concrete repair (driveways, sidewalks) is Polyurethane Sealant, specifically self-leveling varieties.

| Sealant Type | Properties | Best Use Case | Limitations |

|---|---|---|---|

| Polyurethane (Sikaflex, Loctite PL) | High elasticity, excellent adhesion, UV resistant, 5–10+ year durability | Expansion joints, working cracks | Higher cost; requires caulk gun |

| Acrylic/Latex (DAP) | Cheaper, water-based, easy cleanup | Minor surface cracks | Lacks long-term durability in freeze-thaw environments |

| Vinyl Concrete Patch | Cement-based with vinyl resins; rigid | Chipping/spalling repair, rebuilding corners | Cannot accommodate movement; poor for expansion joints |

Polyurethane Advantages:

- Self-Leveling: Flows like thick syrup, filling crack and leveling flat without tooling—crucial for professional-looking DIY results

- Flexibility: Sikaflex remains flexible, accommodating slab movement that caused the crack initially

- Moisture Tolerance: Can adhere to damp concrete (1 hour after water source stops)

Recommendation: For cracks in concrete driveways, Sikaflex Self-Leveling Sealant is widely regarded as the gold standard for DIYers due to ease of use and longevity.

6. Detailed Application Methodologies

Success of any pavement repair is 80% preparation and 20% product. The following protocols maximize DIY repair lifespan.

6.1 Protocol A: Permanent Pothole Repair (Asphalt)

This method utilizes principles of “squaring up” and proper compaction, adapted for DIY tools.

Step 1 — Cleaning (Critical): Remove all loose debris, water, and vegetation. Use wire brush to scrub pothole walls, ensuring patch bonds to solid asphalt rather than dust or mud. If hole is wet, bail out standing water (though Aquaphalt tolerates moisture).

Step 2 — Priming (Optional but Recommended): Apply tack coat (spray adhesive like Tru Tack) on vertical edges. This acts as “glue” between old pavement and new patch, preventing water infiltration at seams.

Step 3 — Filling in Lifts:

- Do not fill deep holes in single application

- Fill in 2-inch “lifts” (layers)

- Compact each layer before adding the next

- This prevents the “marshmallow effect” where surface is hard but center remains soft

Step 4 — Compaction Technique:

- Vehicle Method: Place plywood over slightly overfilled patch. Slowly drive vehicle back and forth over plywood. Vehicle weight provides compressive force far exceeding hand tamping.

Step 5 — Finishing: For QPR/Cold Patch, sprinkle sand or cement dust on top to prevent sticky surface from tracking onto tires. For Aquaphalt, saturate with water and compact.

6.2 Protocol B: Fusion Crack Repair (Asphalt)

Using Pli-Stix or similar melt-in ropes.

Step 1 — Clean: Use screwdriver to scrape out moss and dirt. Blow out with leaf blower or compressor. Ensure crack is dry.

Step 2 — Insert: Lay Pli-Stix rope into crack. For deep cracks, use sand or foam “backer rod” to fill bottom, leaving 1/2 inch depth for filler.

Step 3 — Melt: Use standard propane torch (available for ~$20–30 at hardware stores). Move flame slowly back and forth until rope liquifies and flows into crack.

Step 4 — Safety: Clear dry leaves to prevent fire. Do not overheat to point of boiling or splattering.

Step 5 — Seal (Optional): Apply fine layer of sand over hot tar to texture it and prevent tracking while cooling.

6.3 Protocol C: Self-Leveling Concrete Crack Fix

Using Sikaflex or Loctite PL.

Step 1 — Clean & Dry: Wire brush crack to remove loose concrete and old caulk. Vacuum out dust. Ensure no standing water exists (polyurethanes generally require dry surfaces, though some modern formulations tolerate dampness).

Step 2 — Backer Rod: If crack is deep (goes through slab), stuff foam backer rod into it. This prevents expensive sealant from flowing endlessly into sub-base and allows correct width-to-depth ratio for sealant to stretch.

Step 3 — Pour: Cut nozzle to crack width. Squeeze sealant into crack.

Step 4 — Level: Watch as it settles. Add more if it sinks. No tooling (smoothing with finger) usually required for self-leveling products.

Step 5 — Top Dressing (Optional): To match driveway texture, sprinkle sand over wet sealant.

7. Cost Analysis and Sourcing

Comparative cost analysis helps determine the most economic route for repairs. Prices are estimates based on standard US retailers (Home Depot, Lowes, Amazon) for 2025.

7.1 Product Price Comparison

| Product Category | Brand Example | Unit Size | Approx. Price | Coverage / Yield | Cost Efficiency |

|---|---|---|---|---|---|

| High-End Asphalt Patch | Aquaphalt 6.0 | 50 lb Bucket | $50–$70 | ~5 sq. ft @ 1” thick | Low (Premium) |

| Bulk Asphalt Patch | QPR / Road Rescue | 50 lb Bag | $15–$24 | ~7 sq. ft @ 1” thick | High (Best Value) |

| Asphalt Crack Rope | Latex-ite Pli-Stix | 30 ft Roll | $20–$25 | 30 linear ft | Moderate |

| Asphalt Liquid Filler | Latex-ite / Red Devil | 1 Gallon Jug | $15–$20 | ~150 linear ft | Very High |

| Concrete Sealant | Sikaflex Self-Leveling | 29 oz Tube | $17–$35 | ~70 linear ft (1/4” bead) | Moderate |

| Concrete Patch | Sakrete / Quikrete | 10 lb Box | $10–$20 | ~5 sq. ft @ 1/4” thick | High |

Economic Strategy:

- Small Potholes (< 2 sq ft): Use Aquaphalt. Extra $30 cost is worth permanence and lack of mess.

- Large Potholes (> 5 sq ft): Use QPR or Road Rescue. Large repair with Aquaphalt could cost hundreds; QPR costs a fraction.

- Cracks: Use Pli-Stix for worst cracks (structural/wide) and Liquid Filler for minor cosmetic webs to maintain budget.

8. Weather and Environmental Considerations

Weather is the single biggest factor in repair failure. Immediate need may not align with ideal summer conditions.

8.1 Winter and Wet Weather Application

Most standard repair products fail if applied in winter or rain.

Asphalt: Aquaphalt and Road Rescue are specifically formulated to work in water-filled holes and freezing temperatures. The chemical reaction in Aquaphalt is actually aided by water. However, curing times for traditional cold patches (QPR) slow significantly in cold, remaining soft longer. To aid workability in cold weather, keep bags in warm location until moment of use.

Concrete: Repairing concrete in winter is risky. Most sealants require temperatures above 40°F (4°C) to cure properly. If emergency repair is needed to stop water infiltration, use hydraulic cement (e.g., Drylok Fast Plug), which sets in minutes and stops active leaks—though it is not flexible.

De-icing Considerations: In winter, avoid rock salt on new concrete repairs as it causes scaling. Use magnesium chloride or calcium acetate instead, or simply sand for traction.

8.2 Regional Insights (Pacific Northwest Example)

In regions like King County, WA, where rain is constant and freeze-thaw cycles are frequent:

Drainage is Priority: No patch will last if driveway has poor drainage. Ensuring runoff is cleared is as important as the patch itself. Potholes often form where puddles sit.

Moss Removal: In wet climates, cracks fill with moss. This must be killed (bleach/herbicide) and removed before sealing, or sealant will detach.

Material Choice: Water-based acrylic sealers often wash away before curing in rainy weather. Solvent-based or hot-applied (Pli-Stix) materials are safer options as they are less sensitive to immediate rainfall post-application.

9. Failure Analysis and Future-Proofing

9.1 Common DIY Repair Failures

The “Dish” Effect: When filling a pothole level with ground before compaction, traffic compresses it into a depression. Water collects in the dish, destroys the bond, and creates a new pothole.

- Solution: Overfill hole by 1–2 inches (creating a crown) before compacting so final level is flush or slightly proud of surface.

Dirty Edges: Adhesive in asphalt patch needs to stick to aggregate, not dirt. Failure to sweep the hole leads to edge separation.

Incompatible Chemistries: Using rigid concrete patch on flexible asphalt driveway (or vice versa) guarantees cracking. Materials have different coefficients of thermal expansion.

9.2 Environmental Considerations

Recent trends in “eco-friendly” patches (like Aquaphalt) use binders with zero VOCs (Volatile Organic Compounds). Traditional cutback asphalts release hydrocarbons as they cure. For environmentally conscious homeowners, or those in strict regulatory zones, checking for “No VOC” labeling is advisable. Water-based sealants (like Latex-ite) are lower VOC than solvent-based ones but require better weather windows to cure.

10. Conclusion and Strategic Recommendations

For homeowners seeking low-cost, ready-to-use solutions, the market offers robust options that do not require professional paving crews. The choice depends on balance between budget and longevity.

10.1 Best Value Recommendation (Balance of Cost/Performance)

For Potholes: Use QPR or Road Rescue. Widely available (Home Depot/Lowes), relatively inexpensive ($20/bag), and offer adequate performance for most driveways if compacted thoroughly using vehicle method.

For Cracks: Use Liquid Rubber/Asphalt Emulsion for fine cracks (ease of use) and Latex-ite Pli-Stix for wide cracks (permanence).

10.2 Best Quality Recommendation (Maximum Durability)

For Potholes: Aquaphalt. Essentially “hot mix in a bucket.” Hardens like stone, does not track, and solves the problem permanently.

For Concrete Cracks: Sikaflex Self-Leveling Sealant. Professional-grade elasticity ensures crack stays sealed through winter heave and summer heat.

10.3 Action Plan Summary

- Assess: Categorize damage into “Potholes” vs. “Cracks” and “Asphalt” vs. “Concrete.”

- Purchase:

- Asphalt Pothole: 1–2 bags of QPR/Road Rescue (or Aquaphalt for premium)

- Asphalt Crack: Pli-Stix + Propane Torch

- Concrete Crack: Sikaflex Self-Leveling + Caulk Gun

- Execute:

- Wait for dry day (unless using Aquaphalt)

- Clean thoroughly (wire brush/vacuum)

- Overfill and compact (use vehicle for weight)

- Seal edges (optional tack coat)

By adhering to material limitations and application protocols outlined in this guide, DIY repair can extend driveway service life by several years, deferring thousands of dollars in resurfacing costs.

Appendix A: Tools Required for DIY Repair

| Tool | Purpose | Approximate Cost | Alternative |

|---|---|---|---|

| Tamper (Steel) | Compacting asphalt patch | $30–$50 | Sledgehammer, 4x4 Post, or Vehicle Tire |

| Wire Brush | Cleaning crack walls | $5 | Old stiff broom |

| Propane Torch | Melting Pli-Stix rope | $20–$40 | Heat Gun (slower) |

| Caulk Gun | Applying sealant tubes | $5–$15 | None |

| Leaf Blower | Removing dust/debris | Varies | Shop Vac or Bicycle Pump |

| Squeegee | Spreading liquid sealer | $10–$20 | Old Broom |

Appendix B: Cure Times and Traffic Readiness

| Material | Rain Ready | Foot Traffic | Vehicle Traffic |

|---|---|---|---|

| Aquaphalt | Immediate | Immediate | Immediate |

| QPR / Road Rescue | Immediate | Immediate | Immediate |

| Liquid Crack Filler | 24–48 Hours | 4–12 Hours | 24–48 Hours |

| Pli-Stix (Melted) | Immediate (upon cooling) | 20 Mins | 20 Mins |

| Sikaflex (Concrete) | 1–2 Hours (Tack Free) | 4–6 Hours | 3–5 Days (Full Cure) |

| DAP 3.0 (Concrete) | 3 Hours | 24 Hours | 24 Hours |

Note: “Immediate” for cold patch implies it can be driven on, but it remains soft. Avoid turning wheels while stationary on new patches.

Appendix C: Safety Precautions

Personal Protective Equipment: Always wear gloves (nitrile or leather) when handling asphalt products. Bitumen is sticky and difficult to remove from skin.

Flammability: Cutback asphalts contain solvents. Do not use torches near fresh QPR or liquid sealers until solvents have evaporated.

Burn Hazard: Melted Pli-Stix and hot asphalt can cause severe burns. Wear long pants and boots.

Chemical Safety: Polyurethane sealants contain isocyanates. Use in well-ventilated areas.