Executive Summary of Asphalt Driveway Costs

An investment in an asphalt driveway is a significant financial decision for any homeowner. A comprehensive understanding of the costs, from initial installation to long-term maintenance, is essential for effective budgeting and maximizing return on investment. This report provides a detailed financial analysis of asphalt driveway costs in 2025, deconstructing the price components, examining key influencing factors, and comparing asphalt to viable alternatives to equip homeowners with the necessary data for an informed choice.

💡 Quick Cost Estimate: Need an instant calculation for your driveway project? Use our free Asphalt Driveway Cost Calculator to get accurate estimates for materials, tonnage, and total costs based on your specific dimensions.

💰 National Cost Benchmarks for 2025

The national average cost for a professionally installed asphalt driveway typically falls within the range of $6 to $9 per square foot. This benchmark positions the total project cost for a standard 600-square-foot, two-car driveway between $3,600 and $5,400. The national average for a complete project is approximately $5,263.

However, this average represents only the midpoint of a much broader financial spectrum. The full range of potential costs is significantly wider, accommodating various project scopes and homeowner preferences:

- Budget-friendly installations: $3 to $5 per square foot (favorable site conditions or reclaimed materials)

- High-end projects: $10 to $15 per square foot or higher (premium materials, complex designs, heated systems)

This wide variance underscores a critical point: the “national average” should be viewed as a financial compass for initial orientation, not a precise map of the final destination. The final cost is not a fixed market rate but a variable outcome determined by a combination of deliberate project choices and circumstantial site-specific factors.

📝 Key Budgetary Considerations

The most significant initial determinant of cost is the nature of the project itself. The financial commitment escalates based on the labor and materials required for three distinct project types:

-

Resurfacing (Overlay): The most economical option, costing between $3 and $7 per square foot. This involves applying a new layer of asphalt over an existing, structurally sound base.

-

New Installation: A project on a previously unpaved area, which requires full site preparation, grading, and base installation, costs between $7 and $13 per square foot.

-

Full Replacement: The most expensive scenario, costing from $8 to $15 per square foot. This includes the labor-intensive process of demolishing and removing the old driveway before proceeding with a new installation.

📈 Initial Insights into Long-Term Value

While asphalt generally presents a lower upfront installation cost compared to its primary competitors—concrete ($8 to $18 per square foot) and pavers ($10 to $50 per square foot)—its long-term financial profile is fundamentally different. Asphalt’s economic lifecycle is characterized by a shorter lifespan of 15 to 30 years and a non-negotiable requirement for regular, planned maintenance to achieve that longevity.

The subsequent sections of this report will demonstrate that the long-term value of an asphalt driveway is not inherent in its lower initial price but is realized through a strategic and proactive approach to this maintenance cycle.

| Cost Tier | 💰 Cost Per Square Foot | 💵 Total Project Cost (600 sq. ft.) |

|---|---|---|

| Low-End | $3–$5 | $1,800–$3,000 |

| National Average | $6–$9 | $3,600–$5,400 |

| High-End | $10–$15 | $6,000–$9,000 |

Table 1: National Asphalt Driveway Cost Summary (2025). This table consolidates the key financial metrics for a standard 600 sq. ft. driveway, providing a high-level financial snapshot for initial budget framing.

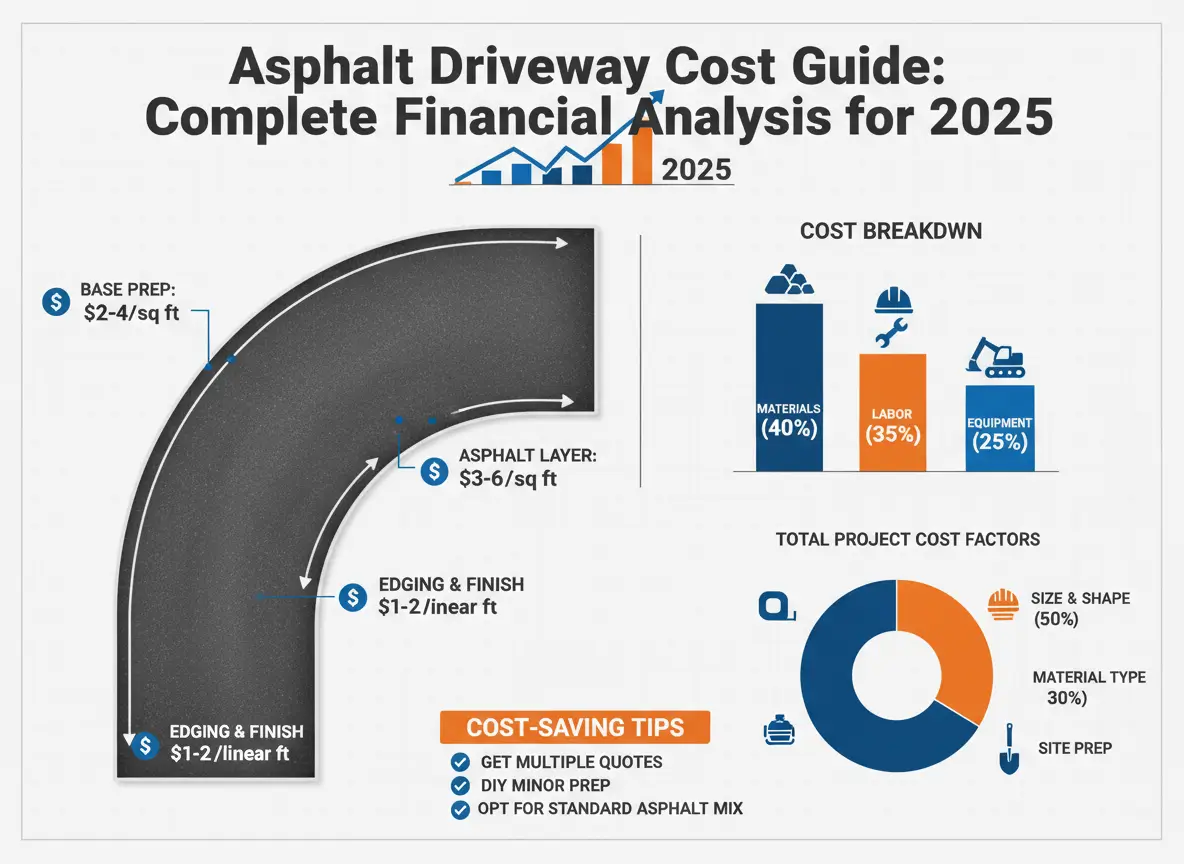

Deconstructing the Price Tag: A Detailed Cost Component Analysis

A contractor’s quote for an asphalt driveway is a composite of numerous distinct expenses. To accurately evaluate bids and understand the project’s financial structure, it is crucial to dissect this total cost into its two primary components: materials and labor.

⚖️ The 50/50 Split: The Balance Between Materials and Labor

As a foundational principle, the total cost of a typical asphalt driveway project is divided almost equally between materials and labor. Labor generally constitutes about 50% of the final project cost, with typical rates ranging from $3 to $7 per square foot. Some contractors may price labor on an hourly basis, with general contracting work falling between $40 and $55 per hour.

This balance highlights that the efficiency and complexity of the installation process are just as impactful on the final price as the raw cost of the asphalt itself.

🧱 Material Expenditures

The material portion of the budget encompasses not only the asphalt but also the critical foundation layers and ancillary products required for a successful installation.

Primary Material - Asphalt

The core component is hot mix asphalt (HMA), a precisely engineered blend of stone, sand, and liquid asphalt cement. The market price for HMA typically ranges from $100 to $200 per ton. The amount of asphalt required is a function of the driveway’s size and thickness.

For a standard 4-inch compacted thickness, one ton of asphalt will cover approximately 40 square feet. Therefore, a 600-square-foot driveway would necessitate around 15 tons of HMA.

🧮 Calculate Your Exact Material Needs: To determine the precise amount of asphalt and associated costs for your specific project dimensions, use our Asphalt Driveway Cost Calculator. The calculator accounts for different mix types, compaction factors, and thickness requirements.

For budget-conscious projects, recycled asphalt pavement (RAP) presents a substantial cost-saving alternative, priced at only $10 to $20 per ton.

Foundation Material - Sub-Base

The longevity of an asphalt surface is directly dependent on the stability of its foundation. A sub-base of crushed stone or gravel provides this essential structural support and facilitates drainage. The cost for this aggregate is approximately $38 per cubic yard or $46 per ton.

For a standard residential driveway requiring a 4 to 6-inch base layer, the material cost for the sub-base alone averages about $0.65 per square foot.

Ancillary Materials

Several other materials are vital to the installation process:

- Tack coat: A bonding agent applied between asphalt layers or at joints with existing pavement to ensure proper adhesion and prevent delamination

- Initial sealant: Many contractors recommend applying an initial sealant to protect the new surface, which adds $0.15 to $0.25 per square foot to the initial project cost

👷 Labor Expenditures

Labor costs are not monolithic; they are distributed across several distinct, often intensive, phases of the project.

Site Preparation

This initial phase is often the most labor-intensive and variable part of the job:

- Demolition and removal (for replacement projects): $1 to $3 per square foot

- Excavation and grading: $1 to $8 per square foot depending on the site’s initial condition and complexity

This critical step ensures the ground is level and sloped correctly for proper water drainage.

Installation & Finishing

This category covers the skilled labor required to operate specialized equipment such as asphalt pavers, plate compactors, and rollers. This work includes:

- Laying and compacting the gravel sub-base to the correct thickness and grade

- Precise application and compaction of the hot mix asphalt

A real-world project example for a 1,685-square-foot driveway replacement showed that the specific line item for “labor and equipment to install crushed rock and asphalt” amounted to $2,974.

Minimum Charges and Mobilization Fees

Homeowners planning smaller projects should be aware that many paving companies have a minimum charge or a minimum asphalt load requirement, such as two tons. This practice covers the significant fixed costs of mobilizing a crew and transporting heavy equipment to the site. These minimums can result in a disproportionately high per-square-foot cost for very small driveways or repair jobs.

Understanding Labor Cost Variability

While material costs like asphalt and aggregate are subject to regional market prices and commodity fluctuations, the most significant cost variable within a contractor’s control—and one that is directly influenced by the homeowner’s property—is labor.

The price of asphalt per ton from a local plant is relatively consistent for all contractors in an area. However, labor costs are directly tied to the time and complexity of the job:

- Simple projects: A flat, rectangular driveway requires a straightforward and efficient process

- Complex projects: A driveway with a steep grade, intricate curves, poor soil that needs remediation, or difficult site access for heavy machinery dramatically increases the man-hours required

This explains why a small but highly complex driveway project may carry a higher per-square-foot cost than a much larger but simpler one, because the labor component constitutes a larger percentage of the total price.

| Cost Component | 💲 Unit Cost | 🔢 Quantity/Units (600 sq. ft. Driveway) | 🟰 Estimated Subtotal |

|---|---|---|---|

| 🧱 Materials | $2,190 - $4,290 | ||

| Hot Mix Asphalt | $130 - $260 / ton | ~15 tons (4” depth) | $1,950 - $3,900 |

| Crushed Stone Base | ~$0.65 / sq. ft. | 600 sq. ft. (4-6” depth) | ~$390 |

| Ancillary (Tack Coat, Sealant) | $0.15 - $0.25 / sq. ft. | 600 sq. ft. (optional sealant) | $0 - $150 |

| 👷 Labor | $2,400 - $4,800 | ||

| Site Prep (Excavation/Grading) | $1 - $3 / sq. ft. | 600 sq. ft. | $600 - $1,800 |

| Demolition & Removal (if needed) | $1 - $3 / sq. ft. | 600 sq. ft. | ($600 - $1,800)* |

| Installation & Finishing | $3 - $5 / sq. ft. | 600 sq. ft. | $1,800 - $3,000 |

| 💰 Estimated Total Project | $7.65 - $15.15 / sq. ft. | $4,590 - $9,090 |

Table 2: Detailed Cost Breakdown: Materials vs. Labor (Per 600 sq. ft. New Installation). Demolition cost is for replacement projects and would replace the standard excavation/grading cost.

The Anatomy of a Quote: Key Factors Influencing Your Final Cost

The final price presented in a contractor’s quote is the culmination of a detailed assessment of numerous project-specific variables. Understanding these factors is crucial for homeowners to interpret their estimates, compare bids intelligently, and identify areas for potential cost management.

📏 Project Scope and Scale

The most fundamental cost driver is the type of project being undertaken. There is a clear cost hierarchy based on the intensity of labor and volume of materials required:

- Resurfacing/overlay: $5 to $7 per square foot (least expensive)

- New construction: $7 to $13 per square foot (mid-range)

- Full replacement: $8 to $15 per square foot (most costly)

📐 Physical Dimensions

The physical characteristics of the driveway directly influence material and labor calculations.

Size

While a larger driveway will invariably have a higher total cost, it often benefits from economies of scale. Fixed costs, such as crew mobilization and equipment transportation, are spread over a larger square footage, which can lead to a lower cost per square foot compared to a very small project.

Shape

The geometry of the driveway is a significant factor:

- Simple rectangular layout: Most efficient and cost-effective to install

- Complex curves or circular portions: Demand more time-consuming and intricate excavation, formwork, and finishing, much of which may need to be done by hand, thereby increasing labor costs

Thickness

The standard thickness for a residential asphalt driveway is between 2 and 4 inches after compaction. However, for properties that will accommodate heavier vehicles like RVs, large trucks, or frequent delivery vehicles, increasing the asphalt thickness to 5 or 6 inches is recommended for enhanced durability and load-bearing capacity. This additional thickness directly increases the volume of asphalt required, adding a significant material cost to the project.

🌱 Site Conditions and Preparation

The existing state of the property is a primary source of cost variability and can introduce expenses not immediately apparent.

Existing Surface and Subgrade

- Undeveloped land: Requires complete excavation, grading, and sub-base installation

- Old driveway replacement: Must include demolition and disposal costs ($1 to $3 per square foot)

- Poor soil conditions: May necessitate additional stabilization measures or a thicker gravel base, potentially increasing project costs by 15-25%

Grading and Drainage

Proper water management is essential for the longevity of any pavement. The site must be graded with a precise slope to direct water runoff away from the home’s foundation and prevent pooling on the driveway surface.

- Standard grading: $1 to $3 per square foot

- Extensive leveling: $40 to $160 per hour for significant slopes or unevenness

Obstructions

Any obstacles on the proposed driveway site must be removed before work can begin. The costs for removing trees, grinding stumps, or breaking up and hauling away large rocks will be added to the total project price.

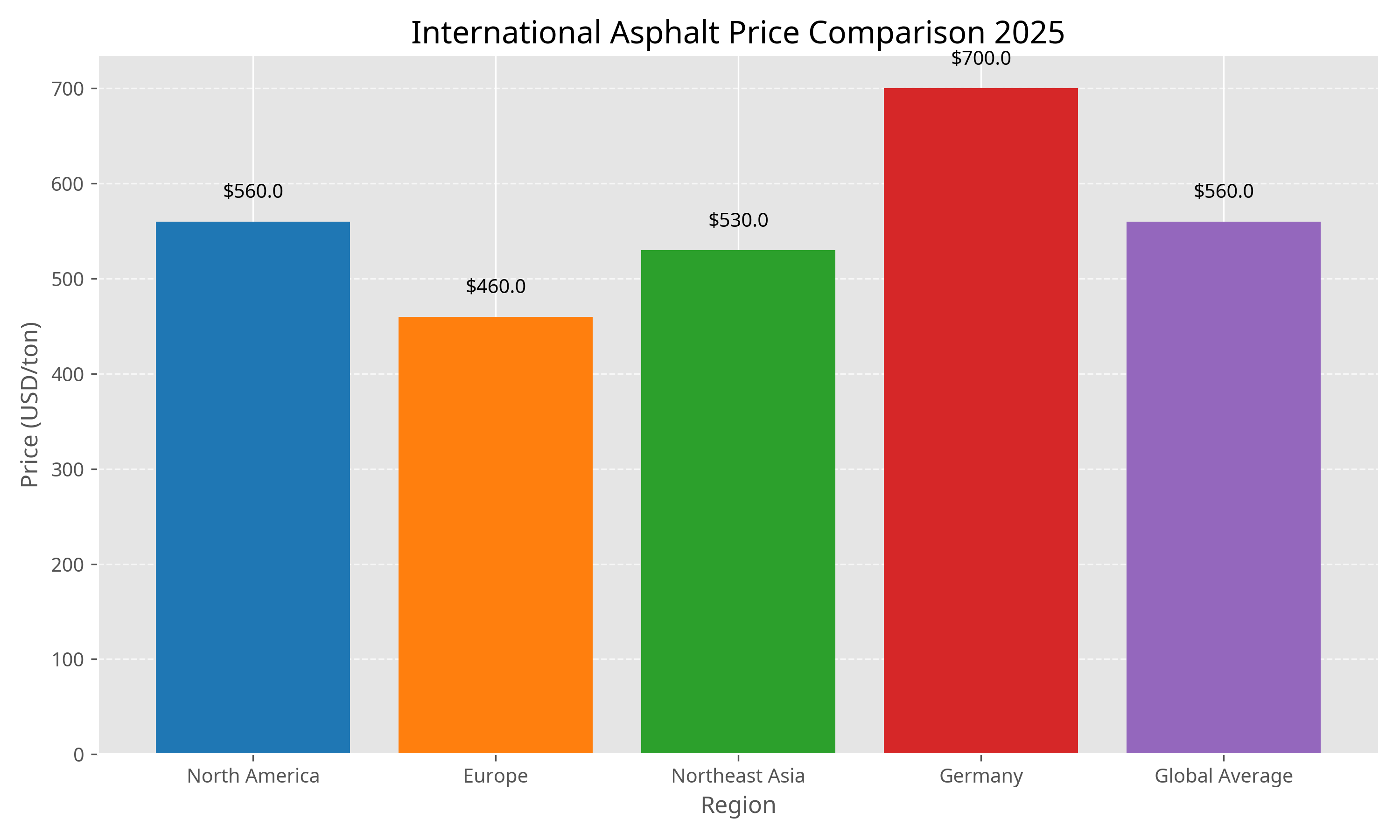

🌍 Geographic and Market Variables

Costs are not uniform across the country; they are subject to local economic and logistical factors.

Regional Price Disparities

Labor and material costs can vary significantly based on geographic location. Labor rates in major urban centers and coastal regions can be 20-40% higher than in rural areas.

For example:

- Northeast: Paving costs tend to be 10-20% higher than the national average

- Midwest and South: Often more affordable

- California (400 sq. ft.): $1,300 to $4,600

- Ohio (400 sq. ft.): $1,200 to $4,200

Material Transport

The proximity of the job site to the asphalt production facility, or “hot plant,” is a direct cost factor. Hot mix asphalt must be transported and applied while it is still at a very high temperature, making transportation time-sensitive and costly, especially for remote locations.

Permits and Regulations

Depending on the municipality, a permit may be required for driveway installation, particularly if it connects to a public road. These permits can range in cost from $50 to over $500. Local building codes may also dictate specific requirements for base thickness or drainage systems.

Seasonality

The demand for paving services is highest in the spring and summer. Scheduling a project during this peak season may lead to higher prices. Conversely, some contractors may offer discounts for projects scheduled during the less busy “shoulder seasons” in the fall.

🎨 Technological and Aesthetic Choices

Finally, the specific type of asphalt and any custom features selected will directly impact the final cost.

Asphalt Type

- Standard hot mix asphalt: $6 to $10 per square foot (baseline)

- Porous asphalt: $7 to $15 per square foot (improved drainage)

- Stamped or colored asphalt: $12 to $20 per square foot (decorative finish)

- Integrated heating systems: $12 to $28 per square foot (snow and ice melting)

Decorative Features

Additional elements such as decorative edging made of pavers or stone, while enhancing curb appeal, are add-ons that will increase the total project cost.

💡 The Value of Proper Site Preparation

A crucial consideration that emerges from this analysis is the financial wisdom of investing in proper site preparation. Homeowners may be tempted to accept a lower bid that minimizes the work done on the sub-base and grading to save on upfront costs. However, this represents a critical false economy.

The data consistently shows that the foundation—the gravel sub-base and the properly graded soil beneath it—is the single most important factor in determining a driveway’s long-term durability. A weak or poorly drained foundation is the primary cause of structural failures like alligator cracking, settling, and potholes, which are costly to repair and can lead to premature failure of the entire driveway.

The cost of a full, premature replacement ($8 to $15 per square foot) far outweighs the initial investment in proper grading ($1 to $3 per square foot) and a sufficiently thick, well-compacted base.

Therefore, the money allocated to thorough site preparation should not be viewed as a mere expense, but as a direct investment that “buys” additional years of service life, ultimately leading to a lower total cost of ownership over the driveway’s lifespan.

The Driveway Dilemma: Asphalt vs. The Alternatives

Choosing the right driveway material is a balancing act between initial budget, long-term performance, maintenance tolerance, and local climate conditions. A thorough comparison of asphalt against its main competitors—gravel, concrete, and pavers—is essential for making a decision that aligns with a homeowner’s specific priorities.

🆚 Head-to-Head Cost Comparison

The initial installation cost is often the first point of comparison, and the differences are stark. The materials fall into clear budgetary tiers:

- Gravel: $1 to $3 per square foot (most economical)

- Asphalt: $6 to $9 per square foot (most affordable paved surface)

- Concrete: $8 to $18 per square foot (more significant upfront investment)

- Pavers: $10 to $50 per square foot (premium category)

⏳ Lifespan and Durability Analysis

The long-term value of a driveway is closely tied to its expected service life. Here, the higher initial cost of some materials begins to correlate with greater longevity.

- Gravel: Up to 100 years (base), though surface requires ongoing attention

- Asphalt: 15 to 30 years (with proper maintenance)

- Concrete: 30 to 50+ years (more durable long-term structural investment)

- Pavers: 25 to 75+ years (depending on material and installation quality)

🔧 The Maintenance Equation

The ongoing commitment of time and money for maintenance varies significantly between materials and is a critical factor in the total cost of ownership.

Gravel

Requires the most frequent hands-on maintenance:

- Regular raking to smooth the surface

- Weed control

- Periodic replenishment of gravel that has been displaced or eroded

Asphalt

Demands a proactive maintenance schedule:

- Sealcoating: Every 3 to 5 years ($1 to $2 per square foot)

- Crack filling: As needed to protect from UV damage and water intrusion

- Repairs are generally simpler and less expensive than concrete repairs

Concrete

Considered a low-maintenance material:

- Susceptible to staining from de-icing salts and chemicals

- Repairs are needed less frequently but are more complex, expensive, and often more noticeable than asphalt patches

Pavers

Offer very low maintenance:

- Primary task is preventing weed growth in joints between pavers

- Major advantage: Individual damaged or stained pavers can be removed and replaced

☀️❄️ Climate as a Deciding Factor

Local climate is one of the most important technical considerations when selecting a driveway material, as extreme temperatures can significantly impact performance and longevity.

Asphalt’s Cold Weather Advantage

Asphalt is widely recognized as the superior material for cold climates that experience significant freeze-thaw cycles:

- Flexibility: Allows the pavement to expand and contract with temperature fluctuations, resisting the cracking that plagues more rigid materials like concrete

- Heat absorption: Dark, black surface absorbs more solar radiation, which helps to melt snow and ice more quickly than lighter-colored concrete, enhancing safety and reducing the need for de-icing chemicals

Concrete’s Hot Weather Advantage

In regions with sustained high heat, concrete holds a distinct advantage. Asphalt can soften in extreme summer temperatures, making it more susceptible to rutting, indentations, and damage from the weight of parked vehicles. Concrete remains rigid and stable in high heat.

💡 Climate-Cost Synergy

The decision between materials should not be based on a single factor, but on the interplay between their properties, the local climate, and the resulting long-term maintenance costs.

For homeowners in colder regions, there is a powerful synergy between asphalt’s physical properties and its financial performance. Because asphalt is more flexible and resistant to damage from freeze-thaw cycles, it is less likely to suffer from the weather-induced cracking that commonly affects concrete in these environments.

Since asphalt repairs are also significantly less expensive than concrete repairs, this physical resilience translates directly into lower long-term maintenance and repair expenditures. In this context, the initial cost savings of choosing asphalt are amplified over its lifespan, making its long-term value proposition in cold climates much stronger than a simple upfront cost comparison would suggest.

| Feature | Gravel | Asphalt | Concrete | Pavers |

|---|---|---|---|---|

| 💰 Installed Cost/Sq. Ft. | $1–$3 | $6–$9 | $8–$18 | $10–$50 |

| ⏳ Lifespan (Years) | Up to 100 (base) | 15–30 | 30–50+ | 25–75+ |

| 🔧 Maintenance | Frequent regrading & replenishment | Sealcoat every 3-5 years; crack filling | Low maintenance; repairs are costly | Low maintenance; spot replacement |

| ☀️❄️ Best Climate | Moderate | Cold (Freeze-Thaw) | Hot | Varies by material |

| 👍 Pros | Lowest initial cost; excellent drainage | Lower initial cost; flexible; fast snow melt | Very durable; low maintenance; customizable | Highest aesthetic appeal; easy repair |

| 👎 Cons | High maintenance; dusty; snow removal is difficult | Requires regular maintenance; softens in heat | High initial cost; cracks in cold; stains | Highest initial cost; potential for weeds |

Table 3: Comprehensive Comparison of Driveway Materials. This matrix provides a side-by-side comparison to aid in the decision-making process, weighing the trade-offs between cost, longevity, maintenance, and climate suitability.

Maximizing Your Investment: Long-Term Value and Maintenance Strategy

The purchase of an asphalt driveway extends far beyond the initial installation. True long-term value is achieved through a strategic approach to ownership, centered on proactive maintenance designed to maximize the asset’s lifespan and minimize its total cost over time.

🔄 The Asphalt Ownership Lifecycle

An asphalt driveway follows a predictable lifecycle:

- Initial installation followed by a curing period of several months

- Stable performance period punctuated by a schedule of required preventative maintenance

- Degradation phase (without maintenance) leading to accelerating repairs

- End of functional life requiring either major resurfacing or complete replacement

Understanding and budgeting for this entire cycle is the key to sound financial management of the asset.

📅 Proactive Preservation: A Schedule of Costs

A proactive maintenance plan can significantly extend a driveway’s life and defer the large capital expense of replacement. The plan involves a hierarchy of interventions, each with an associated cost:

Crack Filling (As Needed, Annually)

This is the most basic and crucial first line of defense:

- Cost: $0.50 to $3.00 per linear foot

- Purpose: Prevents water from penetrating the asphalt and damaging the sub-base, which is the root cause of most major structural failures like potholes and alligator cracking

Sealcoating (Every 3-5 Years)

This is the cornerstone of asphalt preservation:

- Cost: $400 to $800 for a typical two-car driveway ($1 to $2 per square foot)

- Purpose: Protects the asphalt binder from oxidation caused by sun (UV) exposure and prevents water penetration

- Impact: The most effective way to prolong the driveway’s life

Patching/Pothole Repair (As Needed)

When localized damage occurs, it should be addressed promptly:

- Cost: $100 to $500, depending on the size of the repair and method used

- Methods: Temporary cold patch (cheaper) vs. permanent hot-mix asphalt patch

Resurfacing (Overlay) (Once per 10-15 years)

When the driveway surface shows widespread surface cracking but the foundation remains stable:

- Cost: $3 to $7 per square foot

- Process: Applying a new 1.5 to 2-inch layer of asphalt over the old surface

- Impact: Can extend the driveway’s functional life for many years at a fraction of the cost of a full replacement

💰 The Financial Logic of Maintenance

The recurring costs associated with asphalt ownership should not be viewed as unforeseen problems or chores. Instead, they represent a predictable and budgetable series of investments. Each maintenance action is strategically designed to defer a much larger future capital expense—the complete replacement of the driveway.

The data shows a clear cost hierarchy:

- Crack filling: Low-cost task

- Sealcoating: Medium-cost task

- Resurfacing: High-cost intervention

- Replacement: Very high-cost project

There is a direct causal relationship between these actions. Performing the low- and medium-cost tasks on schedule prevents the water intrusion and binder degradation that necessitate the high-cost interventions.

Budget Example (600 sq. ft. driveway)

A financially astute homeowner can model their future cash flows:

- Sealcoating: ~$470 every four years

- Crack filling: Small amount annually

- Result: This predictable, manageable spending pushes the ~$4,800+ cost of a full replacement further into the future

This transforms the “con” of required maintenance into a sound financial strategy with a clear positive return.

👍👎 The Pros and Cons Revisited: A Final Assessment

Considering the entire lifecycle, the value proposition of an asphalt driveway can be summarized as follows:

Pros

- Lower initial installation cost compared to concrete and pavers

- Quick installation process

- Superior performance and durability in cold climates

- Repairs that are generally easier and more affordable

Cons

- Shorter overall lifespan than concrete

- Absolute necessity of a consistent maintenance schedule to reach that lifespan

- Susceptibility to softening and damage in extreme heat

- Limited aesthetic customization options

Key Insight: The long-term cost-effectiveness of asphalt is entirely contingent on the owner’s commitment to the maintenance schedule.

🎯 Strategic Recommendations for Homeowners

To ensure a successful project and maximize the value of the investment, homeowners should follow a structured approach:

1. Solicit Multiple, Detailed Quotes

Always obtain a minimum of three written estimates from reputable, local, and well-reviewed paving contractors. Ensure that each quote is itemized, breaking down the costs for:

- Materials

- Labor

- Site preparation

- Any additional features

2. Evaluate Bids Holistically

The lowest bid is not always the best value. Scrutinize the specifications in each quote, paying close attention to:

- Proposed thickness of the crushed stone base

- Compacted thickness of the asphalt layers

Warning: A low bid that achieves its price by skimping on the foundation is a poor long-term investment that will likely lead to premature failure.

3. Select a Professional Contractor

Choose a contractor who:

- Is transparent about their materials and processes

- Provides clear timelines

- Offers a written contract that details the full scope of work

- Locks in the price to protect against unexpected cost overruns

| Year | 📝 Recommended Activity | 💰 Estimated Cost (600 sq. ft.) | Cumulative Investment (Excl. Installation) |

|---|---|---|---|

| Year 1 (6-9 months) | First Sealcoat | $400 - $800 | $400 - $800 |

| Years 2-4 | Annual Crack Filling (as needed) | $50 - $150 (total over 3 yrs) | $450 - $950 |

| Year 5 | Sealcoat | $400 - $800 | $850 - $1,750 |

| Years 6-8 | Annual Crack Filling (as needed) | $50 - $150 (total over 3 yrs) | $900 - $1,900 |

| Year 9 | Sealcoat | $400 - $800 | $1,300 - $2,700 |

| Years 10-14 | Monitor for extensive surface wear. Budget for potential resurfacing. | ||

| Year 15 | Decision Point: Resurface or continue maintenance. Resurfacing Cost: | $1,800 - $4,200 | $3,100 - $6,900 |

| Years 16-19 | Post-resurfacing maintenance resumes (sealcoating, etc.) | ||

| Year 20+ | Decision Point: Evaluate for full replacement. Replacement Cost: | $4,800 - $9,000 |

Table 4: 20-Year Asphalt Maintenance Schedule and Budget Forecast (Per 600 sq. ft.). This table provides a long-term financial roadmap, allowing homeowners to proactively budget for the total cost of ownership.

Conclusion

An asphalt driveway represents a significant investment that requires careful financial planning and a commitment to ongoing maintenance. While the initial installation cost is lower than many alternatives, the true value of an asphalt driveway is realized through strategic, proactive maintenance that extends its lifespan and defers costly replacements.

Key takeaways for homeowners:

- Budget realistically: Understand that the quoted installation price is just the beginning of the financial commitment

- Invest in quality preparation: Proper site preparation and a solid foundation are non-negotiable for long-term performance

- Commit to maintenance: Regular sealcoating and crack filling are investments, not expenses

- Consider your climate: Asphalt excels in cold climates but may not be the best choice in extreme heat

- Choose contractors carefully: Get multiple detailed bids and select based on value, not just price

By following these principles and maintaining a proactive approach to ownership, homeowners can maximize the return on their asphalt driveway investment and enjoy a durable, functional surface for decades to come.