Abstract: Looking Beyond the Surface Price to Master Your Asphalt Driveway Investment

Paving a new asphalt driveway is an investment involving multiple factors. An effective Asphalt Driveway Cost Calculator is more than just a simple tool for multiplying area by unit price; it is a comprehensive guide that helps you understand complex variables such as material grades, regional variations, sub-base engineering, and long-term maintenance.

Based on in-depth research, this article provides a detailed, illustrated guide that thoroughly analyzes every component of asphalt driveway costs, helping you make decisions that best meet your budget and long-term needs.

I. Asphalt Driveway Paving Cost Overview and Regional Differences

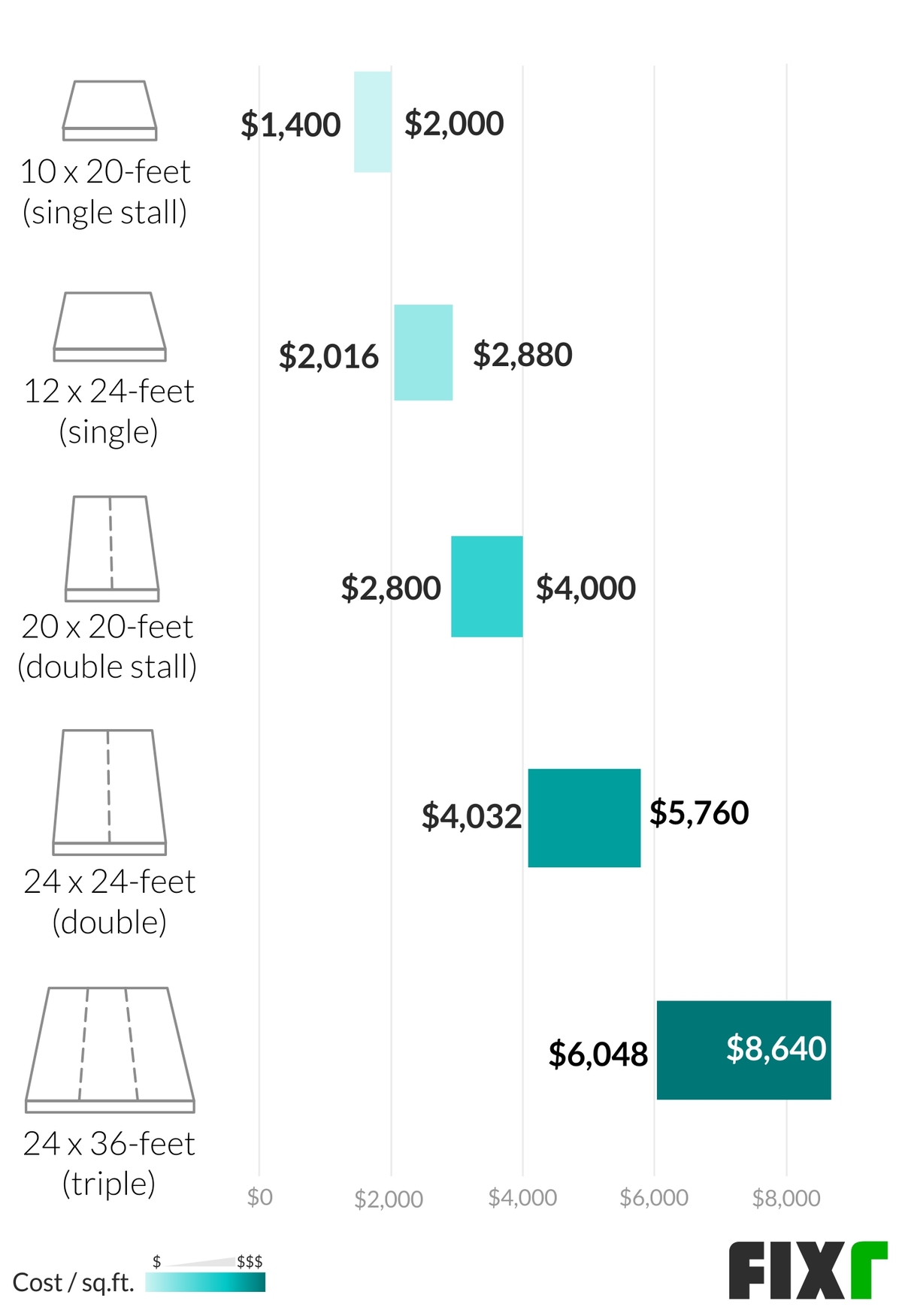

The installation cost of an asphalt driveway is typically calculated per Square Foot (sq. ft.), including both materials and labor.

1. Cost Range and National Average

The installation cost for a standard residential asphalt driveway generally ranges from $3 to $15 per square foot, with a national average cost of approximately $5,265, and most homeowners paying between $3,129 and $7,402.

2. Key Regional Cost Variations

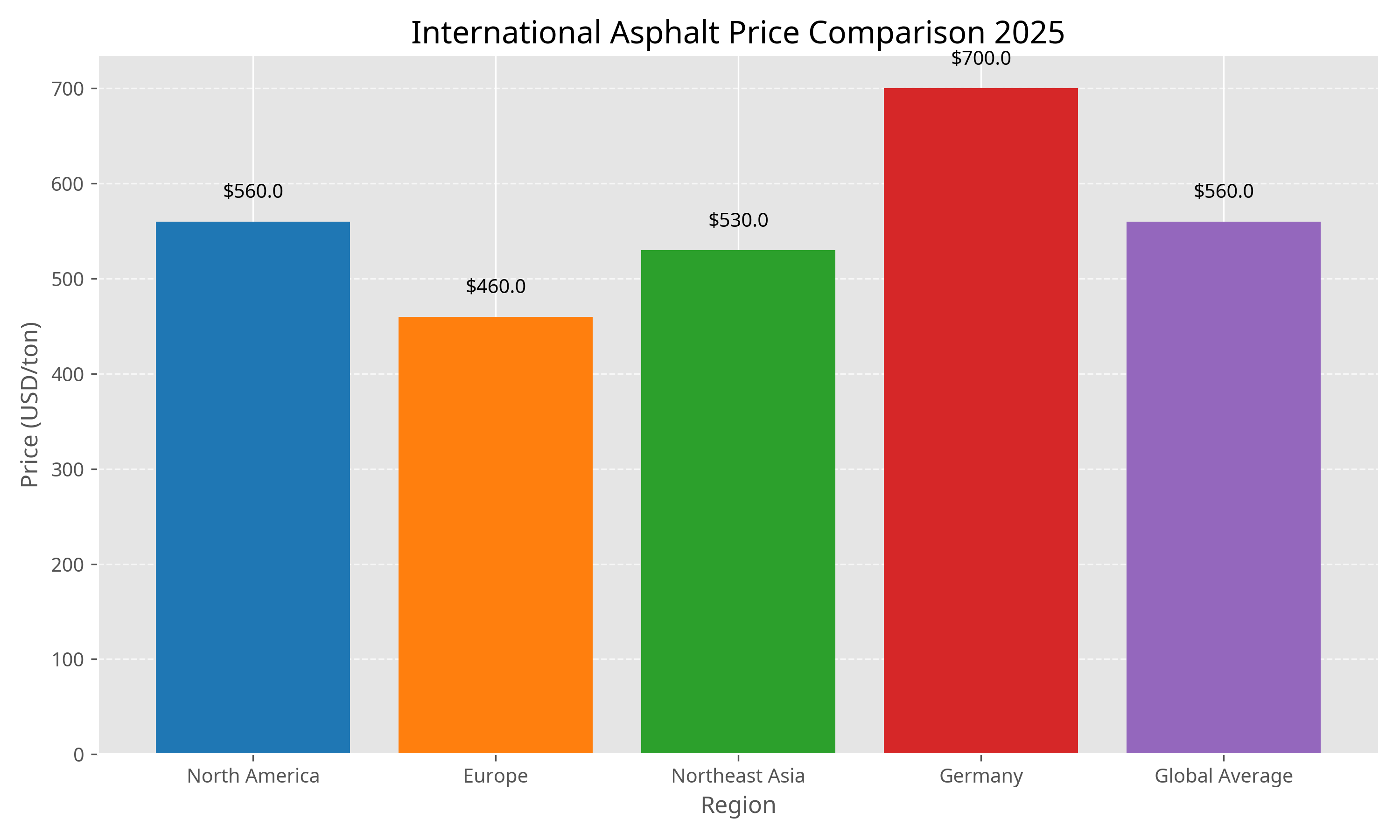

The significant variation in cost is largely dependent on geographic location. The main influencing factors include:

- Raw Material Supply: The transportation distance and local price of asphalt (a crude oil byproduct) and aggregate (crushed stone).

- Labor Costs: Differences in labor rates across various states and cities.

- Climate Conditions: Extreme climate regions (e.g., cold areas requiring more cold-resistant asphalt grades) may necessitate more expensive materials and more complex construction techniques.

| Region | Typical Cost Range per Square Foot (USD) | Influencing Factors |

|---|---|---|

| Northeast/West | $7 - $15+ | High labor and raw material costs, significant climate variation demanding higher material specifications. |

| Midwest/South | $5 - $10 | Relatively lower labor and raw material costs, generally milder climate. |

II. Core Elements of the Cost Calculator: An In-Depth Look at Four Key Factors

An accurate cost estimate must detail the following four core elements:

1. Material Grade and Thickness (Determining Durability)

The choice of material directly determines the driveway’s service life and initial cost.

| Material Type | Description | Typical Lifespan | Application Scenario |

|---|---|---|---|

| Standard Hot Mix Asphalt (HMA) | Dense-Graded, suitable for moderate climates, using a PG 64-22 binder. | 15 - 20 Years | Most residential driveways, balancing cost and performance. |

| Premium Polymer-Modified Asphalt | Polymers added to enhance flexibility and crack resistance. PG 58-28 may be used in colder regions. | 25 - 30 Years | Seeking maximum durability, heavy vehicles, or extreme climate areas. |

| Recycled Asphalt Pavement (RAP) | Uses reclaimed material from old pavement. | 10 - 15 Years | Budget-limited, low-traffic, or temporary driveways. |

Thickness: The recommended thickness for a standard residential driveway is between 3 and 4 inches. Increasing the thickness significantly improves load-bearing capacity and lifespan but proportionally increases material costs.

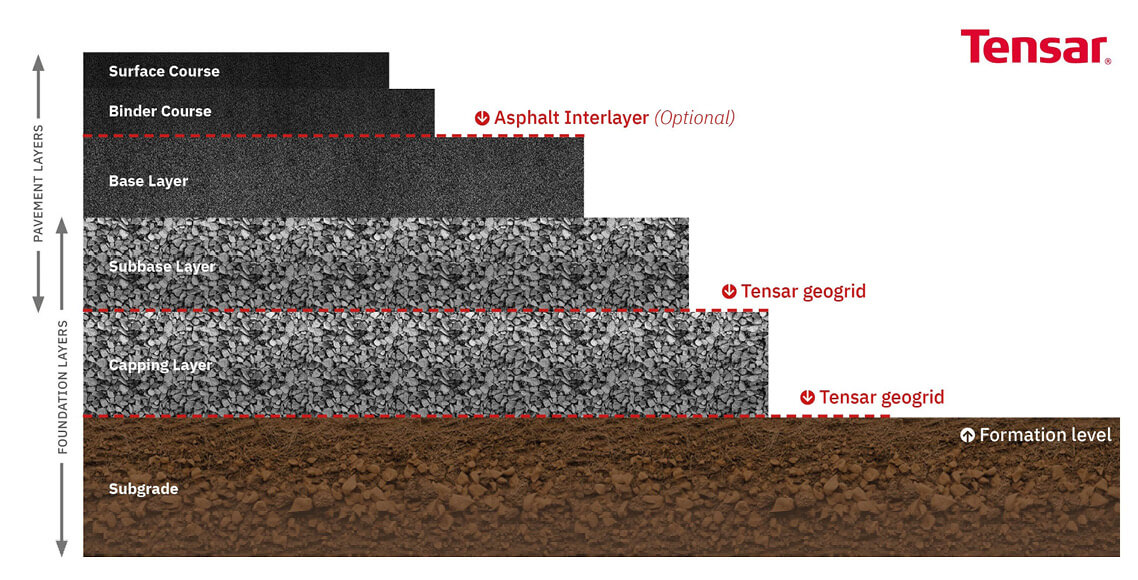

2. Site Preparation and Sub-Base Engineering (Determining Stability)

This is the most easily underestimated cost, yet it is crucial for the driveway’s long-term stability.

- Old Driveway Removal: If an old asphalt or concrete driveway needs to be removed, the cost is typically around $2 to $10 per square foot.

- Sub-Base Layer: The crushed stone base beneath the asphalt layer must be solid and well-draining. The quality of the sub-base directly affects whether the driveway will crack or settle. If the subgrade soil conditions are poor, additional earthwork and reinforcement may be required, significantly increasing the cost.

The image below illustrates the typical layered structure of an asphalt driveway, emphasizing the importance of the sub-base.

Illustration: Typical layered structure of an asphalt driveway, from bottom to top: Subgrade, Base Layer, Binder Course, and Surface Course.

3. Labor and Equipment Costs (Determining Efficiency and Quality)

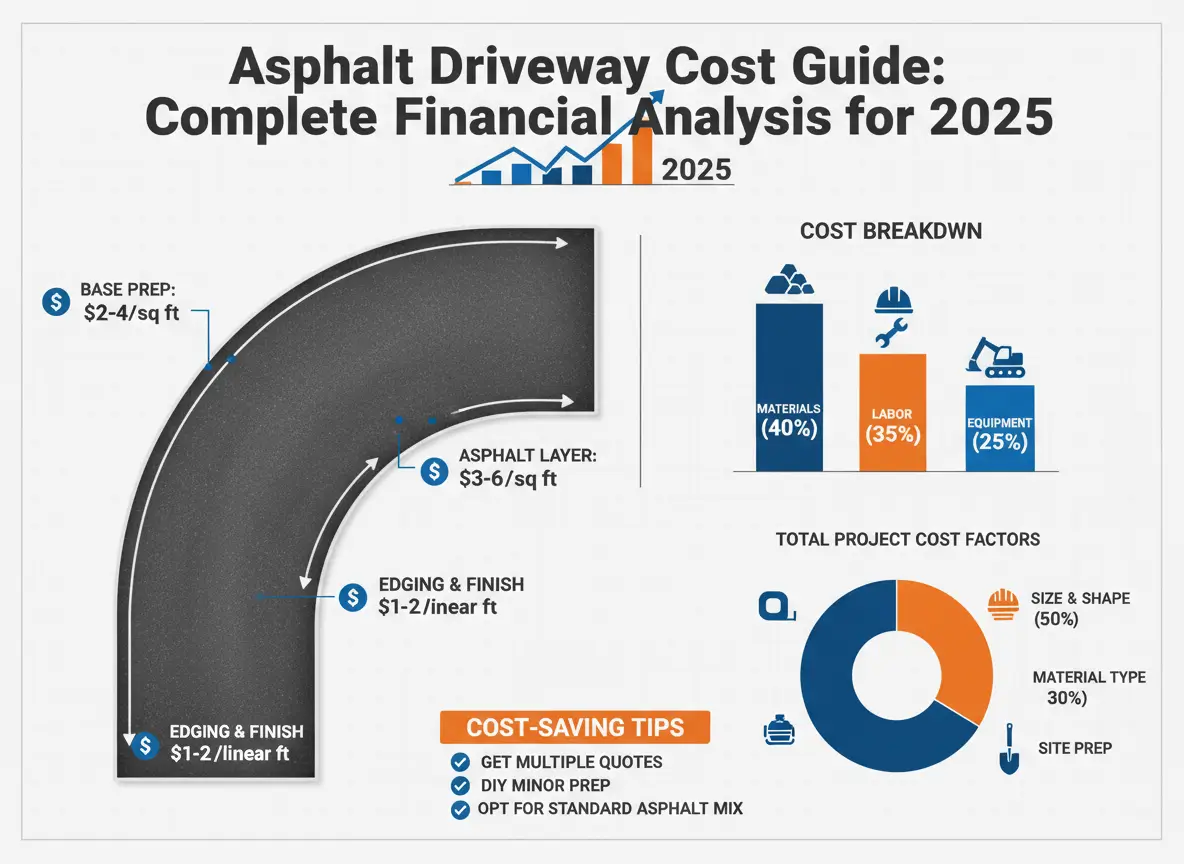

Labor costs typically account for about 40% of the total project cost.

- Labor Cost Range: Generally ranges from $1 to $6 per square foot.

- Project Complexity: Steep slopes, curves, narrow construction spaces, and the need for complex drainage systems will all increase labor costs.

4. Long-Term Maintenance Costs (Determining Total Cost of Ownership)

While asphalt has a lower initial cost than concrete, it requires more regular maintenance to extend its service life.

| Maintenance Item | Frequency | Typical Cost (per sq. ft.) | Notes |

|---|---|---|---|

| Sealcoating | Every 3 - 5 Years | $0.25 - $0.75 | Protects asphalt from water, oil, and UV damage, extending lifespan. |

| Crack Repair | As Needed | $1 - $3 per linear foot | Timely repair of small cracks prevents water from penetrating the sub-base. |

| Overlay | After 15 - 20 Years | 50% - 70% of Initial Cost | Applying a new layer of asphalt over the existing surface. |

Total Cost of Ownership (TCO): Over a 25-year cycle, although asphalt’s initial cost is lower, its TCO may approach or even exceed that of concrete due to the need for multiple sealcoatings and potential overlays. Therefore, maintenance costs must be factored into the budget.

III. Cost Breakdown Diagram and Budget Simulation

The diagram below illustrates the typical breakdown of asphalt driveway costs, helping you visualize budget allocation.

Illustration: Typical breakdown of asphalt driveway costs, with site preparation, asphalt layer, and edging as the main components.

Budget Simulation: Virtual Cost Calculator Steps

To perform a preliminary estimate, follow these steps, simulating the logic of a cost calculator:

- Measure Area: Determine the total area of the driveway (A).

- Select Unit Price: Based on your region and the required material grade (Standard HMA or Premium Polymer-Modified), select an appropriate unit price per square foot (P).

- Calculate Base Cost: $$ \text{Base Cost} = A \times P $$

- Estimate Additional Fees:

- Removal: If needed, multiply the removal area by the removal unit price ($2 - $10/sq. ft.).

- Drainage/Edging: Reserve 10% - 20% of the base cost as a buffer for additional engineering and unforeseen expenses.

- Determine Total Budget: $$ \text{Total Budget} = \text{Base Cost} + \text{Removal Cost} + \text{Additional Fees} $$

IV. Illustrated Paving and Maintenance Process for a Quality Asphalt Driveway

Understanding the paving process helps you oversee the quality of the work and ensure the contractor follows best practices.

| Step | Description | Illustration |

|---|---|---|

| 1. Site Preparation and Layout | Clear old material, grade the ground, ensuring at least a 2% slope for proper drainage. |  |

| 2. Sub-Base Installation and Compaction | Lay and thoroughly compact a 6-8 inch crushed stone sub-base. This is critical for the driveway’s durability. | |

| 3. Asphalt Paving | Lay the Hot Mix Asphalt (HMA), typically in two layers: the Binder Course and the Wearing Course, totaling 3-4 inches in thickness. |  |

| 4. Sealcoating Maintenance | Perform the first sealcoat 6-12 months after paving, and repeat every 3-5 years to protect the surface. |  |

V. Conclusion and Final Budget Recommendations

The Asphalt Driveway Cost Calculator is a powerful planning tool that compels you to consider the quality and long-term value behind the cost.

Final Budget Recommendations:

- Obtain Detailed Quotes: Request written quotes from contractors that clearly specify the asphalt thickness (in inches), sub-base depth, and the asphalt grade used (e.g., PG 64-22).

- Prioritize Quality Over Price: Choosing quality materials and solid sub-base engineering, while having a higher initial cost, can significantly extend the driveway’s lifespan and reduce the frequency of future maintenance and overlays, thereby lowering the Total Cost of Ownership (TCO).

- Reserve a Buffer: Allocate a 15% - 20% buffer in your budget to address potential unforeseen issues during site preparation (such as discovering damaged old sub-base or drainage problems).